Process Pumps

| Standard | Markets | Parameter | |||

|---|---|---|---|---|---|

|

AY(s)/AYP Series Centrifugal Oil Pump | API610(OH2/BB2) |

|

|

|

|

CZ Series Standard Petrochemical Process Pump | ISO5199/ISO2858 |

|

|

|

|

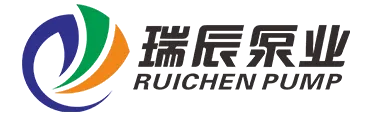

DMS Series Axial Split Multistage Pump | API610(BB3) |

|

|

|

|

DMS Series Horizontal Multistage Pump | API610(BB4) |

|

|

|

|

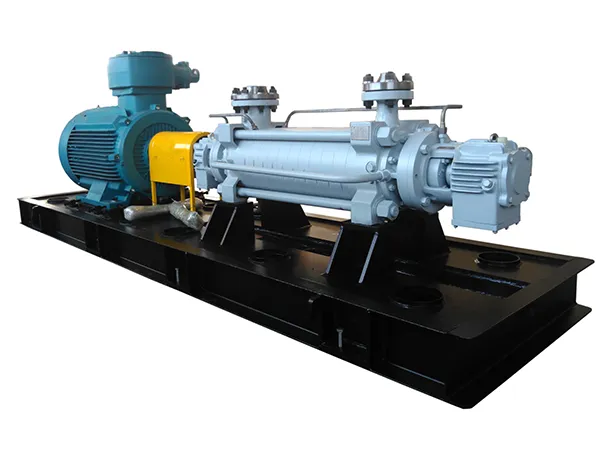

DSG Series Cartridge Double-Shell Horizontal Multistage Pump | API610(BB5) |

|

|

|

|

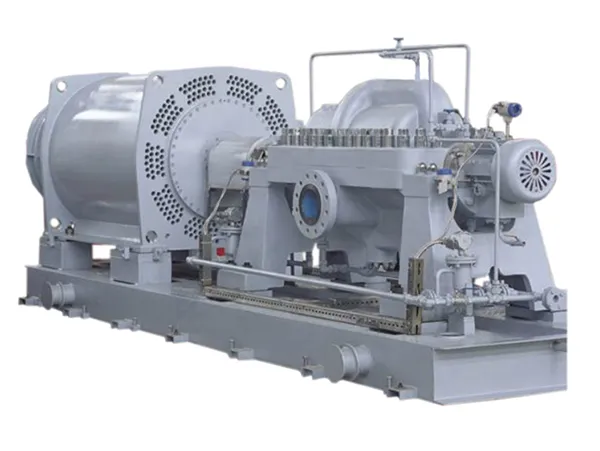

SM Series Axial Split Double Suction Pump | API610(BB1) |

|

|

|

|

XB Series Small Flow Petrochemical Process Pump | API610(OH2) |

|

|

|

|

ZA/ZAO Series Petrochemical Process Pump | API610(OH1) |

|

|

|

|

ZE/ZEO Series Petrochemical Process Pump | API610(OH2) |

|

|

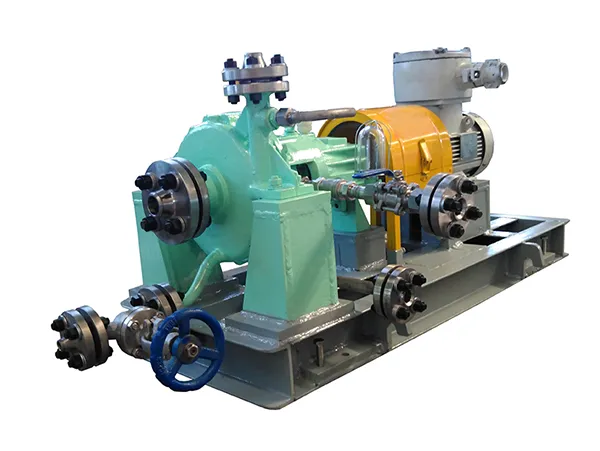

About Process Pumps

Process pumps are designed to handle fluids and materials in industrial processes, such as chemical processing, oil and gas production, and wastewater treatment. They are typically centrifugal pumps that can handle high flow rates and pressures, and are made of materials that can withstand corrosive or abrasive fluids. Process pumps are critical components in many industrial operations, and their reliability and efficiency are key factors in ensuring safe and cost-effective production.

How Does a Process Pump Work?

Process pump works by using a motor to rotate an impeller, which creates a suction force that draws fluid into the pump. The impeller then pushes the fluid through the pump and out of the discharge port. The pump may also have additional components such as seals and bearings to help maintain its operation and prevent leaks. Different types of pumps, such as centrifugal and positive displacement pumps, operate using different mechanisms but generally follow this basic principle.

Process Pump Terms

To obtain a clearer understanding of process pumps, it’s helpful to examine the various terms associated with them. The most common terms used include:

- NPSH: Net Positive Suction Head is the difference between the absolute pressure at the pump suction and the vapor pressure of the liquid being pumped. It is a measure of how much pressure is available at the inlet of the pump to prevent cavitation.

- Cavitation: A phenomenon that occurs when the pressure at the pump inlet drops below the vapor pressure of the fluid being pumped, causing bubbles to form and collapse violently. This can damage the pump and reduce its efficiency.

- Efficiency: The ratio of the output power of the pump to the input power, expressed as a percentage. A higher efficiency means less energy is wasted and more is used to move the fluid.

- Impeller: The rotating component of the pump that generates the flow and pressure of the fluid. It consists of blades or vanes that push the fluid radially outward.

- Seal: A device that prevents fluid from leaking out of the pump along the shaft. There are various types of seals, including mechanical seals, packing seals, and lip seals.

- Motor: 6. The component that provides the power to drive the impeller. It can be electric, hydraulic, or pneumatic, depending on the type of pump.